Tekerlek, Tekerlek Takımı & Boji CNC & Makina

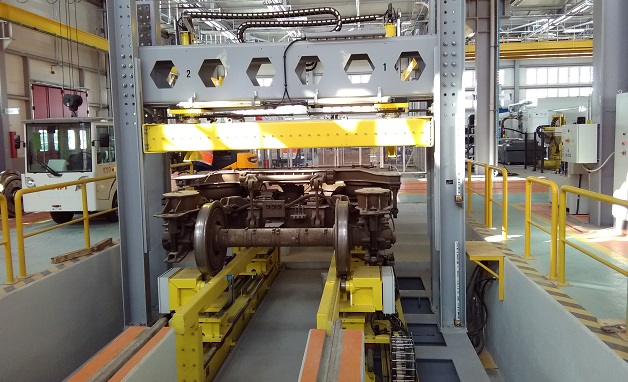

Sabit üst kirişlere sahip Boji Yük Test Standı, bojilerin yük testi ve muayenesi için kullanılır. Test zemin seviyesinde gerçekleştirilir, böylece boji kaldırma işlemine gerek kalmaz. Stand, her türlü boji aks ve tekerlek yükü testlerinde çalışmak üzere tasarlanmıştır. Boji Yük Test Standı, yükseklik testi ve ayar plakasını hesaplamak, taşıma kapasitesi simülasyonlarını ve bilgisayar destekli boji teknik stabilitesini kontrol etmek için boji (tekerlek boyutu, aks paralellik, dingil mesafesi, tekerlek çapı, vb.) Boyut testleri yapabilir. Süspansiyon stabilite testleri ve sürüş yüksekliği ayarlamaları, ölçüm verilerini kaydetmek ve değerlendirmeler yapmak ve bu verilere dayalı raporlar oluşturmak.

Boji Rotasyon Test Standı hem motorlu bojiler hem de taşıyıcı bojiler için kullanılabilir. Rayları indirerek bojileri test etmeyi sağlayan bir yapı. Stand, her iki tarafında 2’si sabit ve diğeri 2’si hareketli olmak üzere 4 destekten oluşur ve bunlar bojiyi yatay eksende konumlandırmak ve dönüş testleri sırasında bojileri destekleyebilmek için gereklidir. Ana test ekipmanı, burç ısı sensörü, tekerlek hız sensörü, fren mikro durumu, kızılötesi ısı sensörleri, dönüş sırasında meydana gelen düzensiz titreşimleri gösteren ivmeölçer gibi konektör bağlantılarıdır. Ayrıca sistem, fren silindirlerinin kapasitesi de dahil olmak üzere tüm fren sistemini performans açısından test edebilmektedir.

Boji Boyut Kontrol Makinesi, karmaşık şekillere ve büyük boyutlara sahip mekanik elemanları test etmek için kullanılır. Bir boji şasisinin boyutsal kontrolü, kullanıcıdan yüksek doğruluk gereksinimleri olan uygun temaslı problarla kalibre edilmiş bir çubuk seti ile yapılır. Kontak çubukları, 3 boyutlu CAD çizimlerini kasadaki dikeyliği ve paralelliğe ilişkin verileri bellekteki örnek küme verileriyle karşılaştıran bir bilgisayara aktarır ve varyasyon olmadan yazdırır. Boji Boyut Kontrol Makinesi, ölçümün kararlılığını sağlamak için titreşim önleyici ped sistemine monte edilen bir beton bloğun üzerine monte edilmiştir.

CNC Tekerlek Takım Torna Tezgahı, zemine ray seviyesinde yerleştirilir ve normal bir torna tezgahının işlevlerine ek olarak sökülmüş tekerlek setleri (hem taşıyıcı hem de motor tahrikli) için aşağıdaki görevleri yerine getirebilir: yeni ve yıpranmış flanşların ( aşınmış tekerleklerin profillerle uyumlu olarak yeniden şekillendirilmesi, iç ve dış flanşların tekerlek jantları) ve fren diski yüzeylerinin şekillendirilmesi. Fren disklerini çıkarmak için titreşimli bir mengene kullanılır. CNC Tekerlek Takım Torna Tezgahı, torna tezgahındaki artıkları çıkarmak için bir talaş konveyörüne sahiptir. Yazılım otomatik olarak yeni profilleri, derinlikleri ve koşu sayısını hesaplar. CNC Tekerlek Takım Torna Tezgahı, her türlü malzemeden tekerlek takımlarını destekleyebilir.