Dinamik Tren Muayene Merkezi

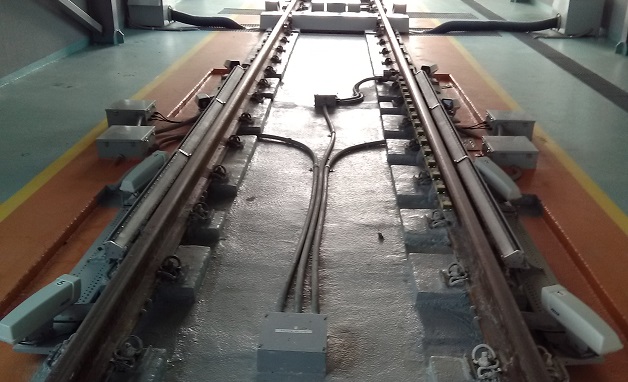

Dinamik tren muayene istasyonu, bir operatöre gerek kalmadan sistem üzerinde hareket ederken her türlü tren tekerleğinin dinamik muayenesini gerçekleştirmek için kullanılır. Sistem temassız ölçüm yöntemleriyle (lazer ve ultrason teknolojileri gibi) çalışır ve her tren geçişini yazılım veritabanındaki her tren tekerleğine ayrılmış bir geçmişle kaydeder. RFID teknolojisi sayesinde, sistem yazılım tarafından ölçülen ve hesaplanan verileri bu otomatik ekipman tanımlaması (AEI) ile ilişkili tren numarasıyla ilişkilendirebilir. Sistem her zaman uyku modundadır ve yalnızca bir tren sistemden geçmek üzereyken açılır.

- Çok hatlı lazerli ve yüksek hızlı kameralı tekerlekleri ölçmek için lazer kamera teknolojisini kullanan tekerlek profili göstergesi,

- Lastik sırtı ve arıza koşullarını gözlemlemek ve değerlendirmek için tekerlek çevresinin görüntülerini yakalamak için birden fazla kamera kullanan optik tekerlek hatası algılama,

- Düşük hızda haddeleme plakası yapılandırması ile tekerlek anormalliklerini tespit eden düz nokta ve salgı algılama,

- Her biri tek satır lazer ve yüksek hızlı kameradan oluşan bir dizi ölçüm bölmesi ile disk frenlerinin kalınlığını ölçmek için lazer kamera teknolojisini kullanan fren balatası izleme.

Dinamik Tren Muayene İstasyonu gerçek bir modüler sistemdir, çünkü entegre sistemden biri veya istediğiniz kadarı bunun bir parçası olabilir. Sistem, ihtiyaçlarınıza bağlı olarak içeride veya dışarıda yapılabilir. Rayların üzerinde herhangi bir yerin ortasına yerleştirilebilir veya bir bakım deposunda kendi altyapısına sahip olabilir. Sensörler çok hassas olduğu için bu sistemi diğer sistemlerin bulunduğu bir binaya iç mekanlara yerleştirmenizi önermiyoruz. Sistem fazla yer gerektirmez, çünkü her şey doğrudan kabin (elektrik ve bilgisayar) ile raylara monte edilir. Sistem, yıllık kalibrasyon ve kontroller ile kamera ve lazerlerin düzenli olarak temizlenmesi dışında fazla bakım gerektirmez.