Yüksek Hızlı Tren Bakım Kompleksi Ankara

Ankara Yüksek Hızlı Tren Bakım Kompleksi, Türkiye’nin ilk yüksek hızlı tren bakım kompleksidir. Daha önceden, CAF yüksek hızlı trenlerinin Ankara TCDD konvansiyonel deposunda, tüm yüksek hızlı tren setlerinin bakım operasyonlarını düzgün bir şekilde gerçekleştiremeyen, sınırlı malzeme ve oda ile servis bakımı yapıldı. Bu nedenle, SIEMENS trenlerinin gelişiyle, TCDD, tüm ağır bakım işlemleri de dahil olmak üzere A’dan Z’ye tüm bakım görevlerini yapacak malzemeli yüksek hızlı trenler için bir depo projesini planlamaya karar verdi. Bu projenin gerçekleştirilmesi Temmuz 2013 ile Haziran 2017 arasında, 153.000.000,00 € başlangıç bütçesiyle gerçekleştirildi.

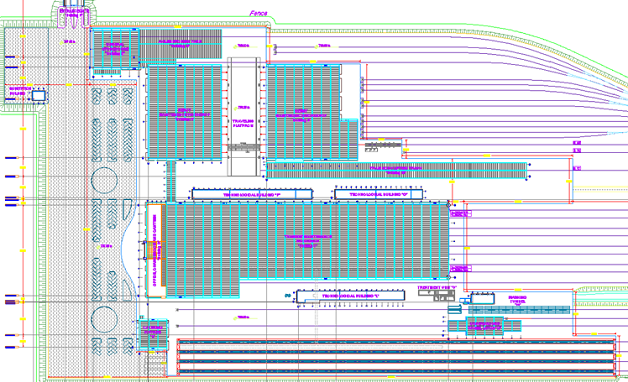

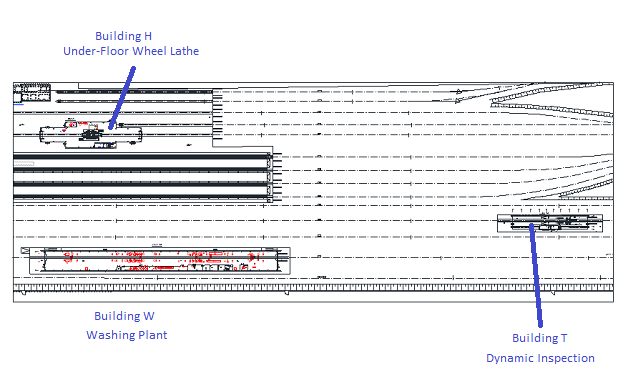

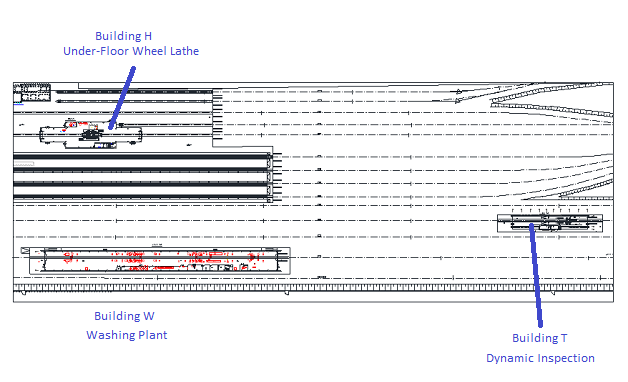

ITALFERR şirketi ile ortaklaşa Ankara Yüksek Hızlı Tren Bakım Tesisi projesinde hızlı trenlerin bakımı için gerekli tasarım ve bakım sistemleri konusunda danışmanlık yaptık. Şeker Fabrikası saha alanının geniş, potansiyel, genişletilebilir alanı ve alanın hemen arkasından geçen yüksek hızlı hattı nedeniyle projenin gerçekleştirilmesine uygun olduğuna karar verilmiştir. Tüm proje 15 bina, 109 farklı atölye ekipmanı ve toplam 373 ekipmanı içermektedir.

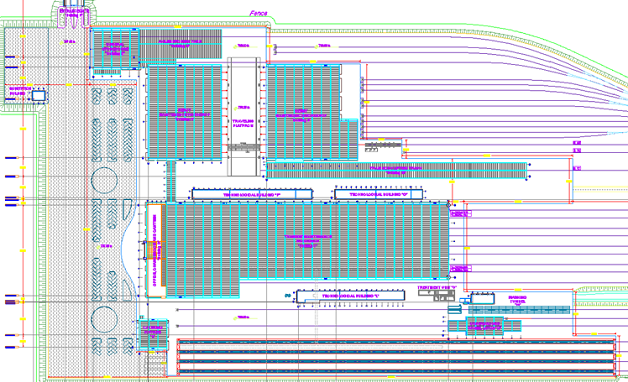

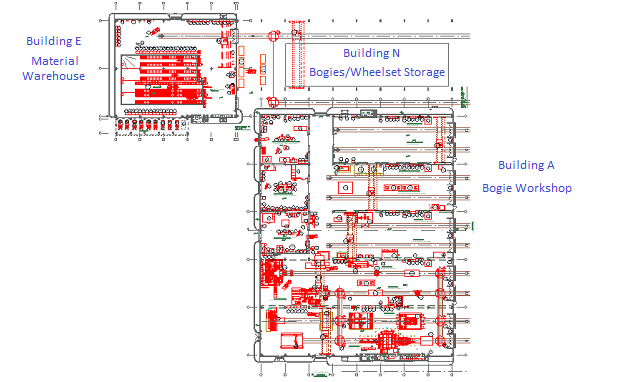

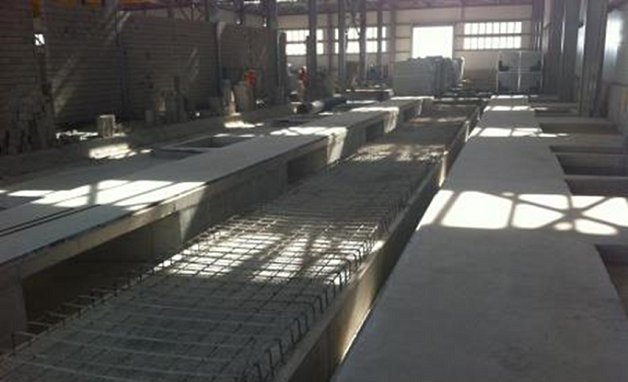

A Binası : Boji Atölyesi, bojilerin ağır bakımlarının yapıldığı yerdir. Şasinin, tekerlek setleri, akslar, tekerlekler ve daha küçük bileşenler gibi bojinin tüm parçaları, bakım süresinin sonunda tamamen işlevsel bir bojiye sahip olmak için sökülüp takılır, test edilir, geliştirilir ve veya değiştirilir. Bu bina, 118 atölye ekipmanı içeren makine sayısıyla ve 61 değişik atölye için farklı makinelere sahip olmasıyla tesisin en iyi döşenmiş yeridir.

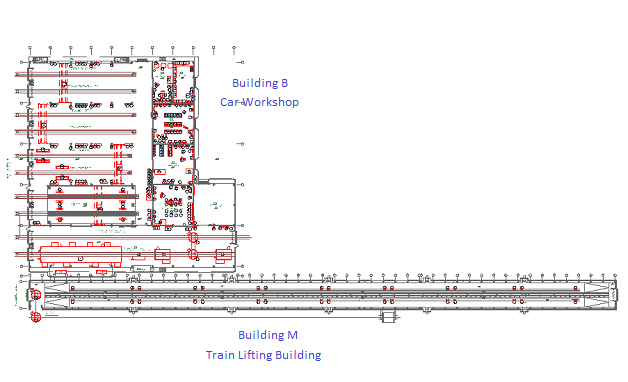

B Binası: Vagon Atölyesi, vagonların ağır bakımlarının yapıldığı yerdir. Bu binadaki işler, yüksek hızlı tren vagonları M binasında (Tren Kaldırma Binası) birbirinden ayrıldıktan sonra tüm bir vagon üzerinde yapılır. Vagon kaldırma, tavan kontrolü, boji değişiklikleri, dış boyanın yenilenmesi, pil şarjı vb. … orada gerçekleşir. Bu bina ve alt atölyeleri 81 atölye ekipmanı ve 27 farklı atölye ekipmanı içermektedir.

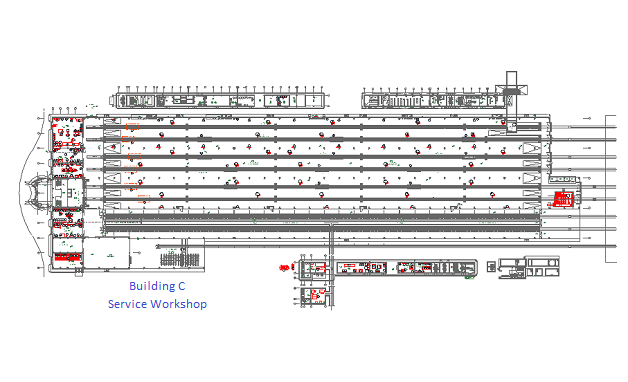

C Binası: Servis Atölyesi, trenlerin servis operasyonlarının yapıldığı yerdir. Trenler gün içinde gelip sadece kısa bir süre kaldıklarından iş operasyonlarının süresi çok önemlidir. Vagon içi temizlik, kumlama, boji değişiklikleri, tekerlek takımı değişiklikleri vb. işlemler orada gerçekleşir. Bu bina ve alt atölyeleri 104 atölye ekipmanı ve 35 farklı atölye ekipmanı içermektedir.

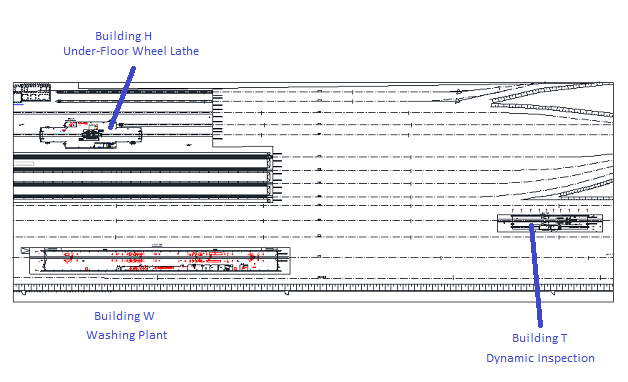

H Binası: Zemin Altı Tekerlek Tornası, tren tekerleklerinin kesildiği yerdir. Tüm tren bir ray veya makaslı rayın izlediği binaya girer ve CNC Tandem Zemin Altı Tekerlek Tornası aynı anda bir tam boji (4 tekerlek) üzerinde çalışabilir. Her bir tekerlek profili ölçülür ve operatör, tekerleğin kesilmesi için uygulanacak değerlere karar verir. Bu makinenin düzgün çalışması için özel bir bina gereklidir. Bu yüzden bu binada sadece 2 farklı atölye ekipmanı var.

Bina M: Tren Kaldırma Binası, tüm trenin senkronize olarak kaldırıldığı yerdir. Trenin arabalarını birbirinden sökmek ve bojileri değiştirmek için kullanılır. Bu binadan ayrıldıktan sonra A binasına bir boji veya ağır bakım işleri için bir lokomotif nakliyesi ile B binasına bir araba gönderilir. Bu bina sadece 1 kaldırma krikosu sistemi ve düşme çukurundan gelen bojiler için 2 boji döner tabla içerir.

T Binası: Dinamik Muayene, geçen bir trenin her tekerleğinin / aksının / bojisinin dinamik kontrolü ve ölçümü için kullanılır. Lazer sistemi hassas ölçümlere izin verir ve herhangi bir tekerleğin herhangi bir sorunu olup olmadığını ve H Binasında değiştirilmesi veya yeniden düzeltilmesi gerektiğini belirler. Bu makinenin düzgün çalışması için özel bir bina gereklidir. Bu yüzden bu bina sadece Otomatik Tren Dinamik Denetim İstasyonu içerir.

W Binası: Yıkama Tesisi trenlerin yıkandığı yerdir. Tüm tren, bir Ray veya makaslı ray tarafından izlenen binaya girer ve Otomatik Tren Dış Gövde Yıkama trenin ayrıntılı olarak yıkanmasına özen gösterir. Bu makinenin düzgün çalışması için özel bir bina gereklidir ve tanklardaki suyun buz haline gelmesini ve boru sistemine zarar vermesini önlemek için binanın sıcaklığı kontrol edilmelidir. Bu yüzden bu binada sadece 2 farklı atölye ekipmanı var.