Test Ekipmanları & Tezgahları

Motor Rotoru Denge Test Tezgâhı, elektrik motoru rotorlarının dengesinin uygunluğunu doğrulamak için kullanılır. Motor Rotoru Denge Test Tezgâhı, tasarımı sayesinde kalibrasyon prosedürlerini basitleştirir ve çok daha doğru ölçümlerin yapılmasına olanak sağlar. Ölçümler tamamen otomatiktir ve dengeyi bozan unsurlara dair detaylı rapor verir.

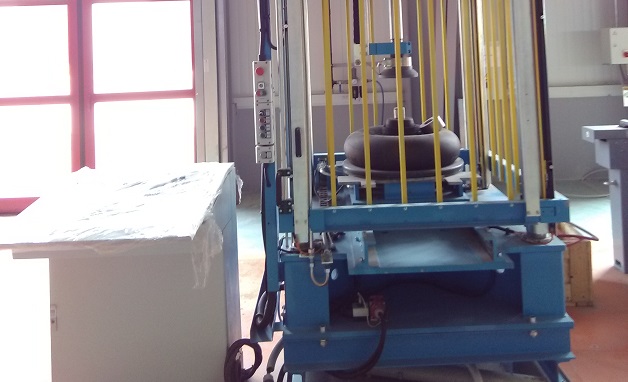

İçi Boş Akslar için Ultrasonik Test Tezgâhı demiryolu taşıtlarına monte edilmiş olan aksların ultrasonik muayenesini yapmak için kullanılan mobil bir test tezgahıdır. Sistem, ultrasonik sondalar içeren bir tutucu kafa, bir motor ve sonda kafasının eksenel yönde dönmesi için bir dişli ünitesi ve ultrasonik sinyallerin iletildiği bir kayma halkası sistemi içerir. Bu mekanizma, besleme birimini diğer aks türlerine monte etmek için tasarlanmış yeni mekanizmalar için parçalara ayrılır.