IZBAN İzmir Banliyö Bakım Tesisi

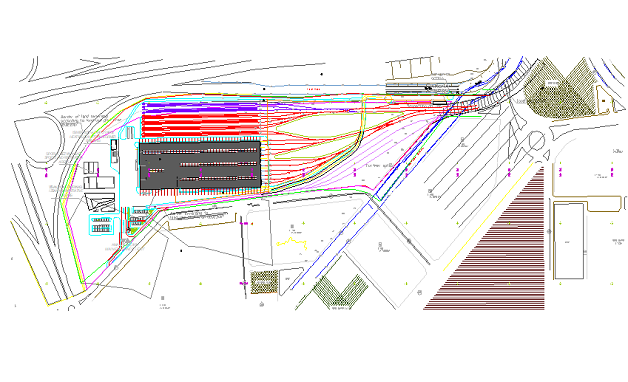

Bu tesis İzmir’de banliyö treni için bir bakım tesisidir. Bu atölye, tüm ağır bakım işlemleri de dahil olmak üzere, A’dan Z’ye araçların bakım görevlerini yapmak için gerekli tüm malzeme ve ekipmanları içerir. Bu projenin gerçekleştirilmesi Şubat 2010 ile Nisan 2013 arasında, başlangıç bütçesi 15.000.000,00 € ile gerçekleşti. Üzerinde çalıştığımız tüm dünyadaki tedarikçilerden birçok farklı makineye (22 si farklı toplam 35 makine) sahip ilk anahtar teslimi projedir. Eda Endüstriyel olarak proje tasarımına ve projenin inşaat çalışmalarında yer alınmıştır.

İZBAN İzmir Tren Bakım Tesisi için sözleşmemizin bir kısmı Otomatik Tren Dış Gövde Yıkama Tesisi, Bakım Tesisinin tasarımını ve yapımını içeriyordu. Proje bölümümüz aynı zamanda ana bina içindeki bazı inşaat işlerini de içermektedir. Bu inşaat işi, inşaat iş ortağımız Arma Grup İnşaat Sanayi ve Ticaret Ltd. Şti. tarafından gerçekleştirilmiştir.

İZBAN İzmir Banliyö Bakım Tesisi için sözleşmemizin bir kısmı teslim ettiğimiz atölye ekipmanlarının temellerinin inşaat işlerini içeriyordu. Bir makinenin temeli, ekipmanın kurulumunun en önemli parçasıdır. Temeller doğru yapılmazsa (boyutlar, düzlük vb.), bir ekipmanın çalışması sırasında önemli sorunlar ortaya çıkabilir. Bu yüzden makinelerimizin temelleri konusunda en az danışman olarak daima yer alıyoruz.

Bakım Tesisleri Ekipmanları, genellikle kendi binalarının, alanlarının optimum koşullarda çalışmasını gerektiren, tam tren uzunluğunda çalışan teknolojik gelişmiş bakım sistemleridir. Bu proje bunlardan 3 tanesini içeriyor: Otomatik Tren Dış Gövde Yıkama Tesisi (ayrı bir bina), Otomatik Tren Dinamik Muayene İstasyonu (dış alan sistemi) ve CNC Tandem Yer Altı Tekerlek Torna (ana bina).

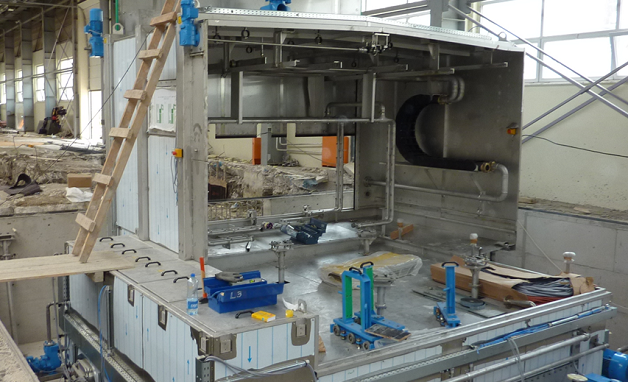

Kaldırma ve Dönme Makineleri, bu projenin ekipman sayısında en önemli parçasıdır. Bu atölyedeki 12 Makina Şunlardır: 2 Döşeme Altı Tüm Treni Kaldırma Sistemi, 1 adet Tüm Treni Kaldırma Krikosu Sistemi,3 adet Boji Döner Tabla, 4 adet Boji şasisi Kaldırma ve Döndürme Sistemi ve 2 adet Açılabilir Boji Kaldırma Pisti.

Boji Test Makinesi, İZBAN İzmir Banliyö Bakım Tesisi projesinin ağır bakım kısmıdır. Trenin vagonlarından ayrıldıktan sonra, bojilerin bu makinelerle yıkanması, kontrol edilmesi ve monte edilmesi ve sökülmesi gerekir. Bu atölye ekipman kategorisinde 3 makine yer alır: 1 Boji Yük Test Standı, 1 Boji Yıkama Makinesi ve 1 Tekerlek Montaj Pres Makinesi.

İZBAN İzmir Banliyö Bakım Tesisi projesine birkaç Test Ekipmanı ve diğer birçok Sistem dahil edildi. Toplam 13 parçadan oluşan sistemler şu şekildedir: 1 Yay Test Tezgahı, 1 Amortisör Test Tezgahı, 2 Mobil Çatı Çalışma Platformu, 1 Geri Açılabilir Katener Sistemi Yolu, 2 Gezer Vinç ve 6 Tek Kriş Vinç.

İZBAN İzmir Banliyö Bakım Tesisi projesi 4 adet Atölye Demiryolu Aracı içermektedir: 1 adet Karayolu Demiryolu Manevra Aracı, 1 adet Tam Teçhizat ile donatılmış Demiryolu Acil Durum Aracı (depoda veya paletlerde Acil Durum veya Kaza durumunda kullanılacak) ve 1 Elektrikli Forklift.